Uhlelo lwebhokisi elibandayo le-distillation tower

1. Kusetshenziswa isofthiwe yokubala ethuthukisiwe, ngokusekelwe ezimweni zesimo sezulu somsebenzisi kanye nezimo zobunjiniyela bomphakathi, kuhlanganiswe nokuhlangenwe nakho kwangempela kwamakhulu emiklamo nemisebenzi yokuhlukanisa umoya, kubalwa ukugeleza kwenqubo kanye nokubalwa kombhoshongo wokuhluza wemishini yokuhlukanisa umoya kuyenziwa, ngokuphepha nokuthembeka njengesisekelo sokuklama:

1) Kusethwe uhlelo oluyinhloko lokupholisa ukuze kuvinjelwe ukukhiqizwa kukagesi ongashintshi;

2) Isakhiwo esiyingqayizivele esiyinhloko sokupholisa esingaqhumiyo sisethelwe ukuvimbela ama-compound e-nitrogen ne-hydrogen ukuthi angaqongelelani emaphikweni;

3) Ukucaciswa okuqinile kokusebenza nokusetshenziswa, kanye nokutholwa okuqinile kwezinga eliyinhloko loketshezi olupholile kanye ne-CnHm sekusethiwe.

4) Khetha ngokufanele izinga lokugeleza kwamagesi ahlukahlukene, ikakhulukazi izinga lokugeleza komoya-mpilo ocindezelwe kanye nomoya-mpilo owuketshezi, ukuqinisekisa ukuphepha; 2. Umbhoshongo wokuhluza usebenzisa umbhoshongo wokupakisha ojwayelekile, onezici zokuguquguquka okukhulu kokusebenza, ukusebenza kahle okuphezulu, ukumelana okuphansi, kanye nokusetshenziswa kwamandla okuphansi;

3. I-heat exchanger eyinhloko isebenzisa ipuleti elide, i-aluminium plate-fin ehlanganisiwe ene-vacuum braced enkulu, enciphisa umehluko wokushisa engxenyeni eshisayo, ilawula ukulahleka kokubanda, futhi inciphise ukusetshenziswa kwamandla;

4. Ipayipi elisembhoshongweni lihlaziywe ngokucindezeleka, ipayipi lisebenzisa ifomu lokuzikhokhela, umzimba wombhoshongo kanye nepayipi kwenziwa nge-aluminium alloy, kanti umzimba wombhoshongo, ipayipi kanye nevalvu kushintshwa nge-argon arc welding; ukuhlolwa okungabhubhisi okungu-100%, ngokuhambisana nezindinganiso zikazwelonke.

Isandisi se-turbine (i-oyela kanye ne-gas bearing)

1. Sebenzisa isofthiwe yokuklama nokucubungula ethuthukisiwe ukuklama nokucubungula ukusebenza kanye neziteshi zokugeleza, ukuze ukusebenza kahle kufinyelele inani elifanele lokuklama, futhi ukusebenza kwe-aerodynamic kanye nokusatshalaliswa kwensimu yokugeleza kube okunengqondo kakhudlwana;

2. Ngenkathi kuqinisekiswa ukusebenza kahle okuphezulu kwesandisi kanye nokusebenza kahle okuphezulu kwesikhulisi, qinisekisa ukufana phakathi kwalokhu okubili kanye nokuzivumelanisa nezimo zokusebenza eziguquguqukayo;

3. I-impeller isebenzisa umklamo wokugeleza onezinhlangothi ezintathu futhi icutshungulwa umshini wokugaya we-CNC othuthukisiwe ukuqinisekisa ukunemba kokucubungula kwe-impeller;

4. Sebenzisa i-nozzle elungisekayo ukuze ulungise umthamo wokupholisa.

Isandisi Sokuthwala Igesi

Isandisi Sokuthwala Amafutha

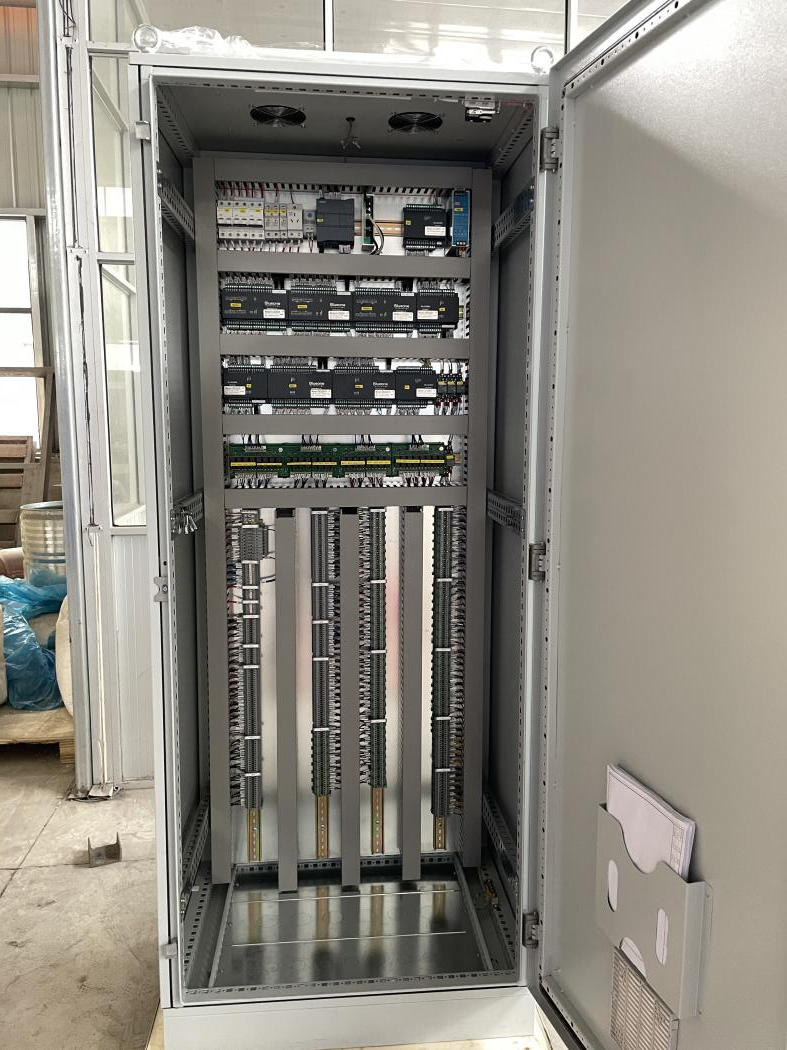

Uhlelo lokulawula izinsimbi kanye nogesi

1. Sebenzisa indlela yokulawula ehlanganisa igumbi lokulawula eliphakathi kanye nekhabhinethi eseceleni komshini ukuze kuqashwe kahle isethi ephelele yemishini yokuhlukanisa umoya;

2. Sebenzisa uhlelo lokulawula izinsimbi ze-DCS (PLC) ukuqedela ukubonisa, i-alamu kanye nokulawula amapharamitha enqubo eyinhloko;

3. Yakha futhi ukhiqize ngokuphephile nangokuthembekile ngokuhambisana nezindinganiso nezincazelo zezwe laseShayina nezemboni;

4. Setha ikhabhinethi eseceleni komshini eduze kweyunithi ngayinye ukuze ufeze ukusebenza endaweni.

Noma yimuphi umoya-mpilo/i-nitrogen/i-argonizidingo, sicela usithinte:

Emma Lv Tel./Whatsapp/Wechat:+86-15268513609

Email:Emma.Lv@fankeintra.com

Isikhathi sokuthunyelwe: Ephreli-29-2025

Ucingo: 0086-15531448603

Ucingo: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com