Iyunithi yokuhlukanisa umoya ye-KDON-32000/19000 iyiyunithi eyinhloko yokusekela ubunjiniyela bomphakathi yephrojekthi ye-ethylene glycol engu-200,000 t/a. Ihlinzeka kakhulu nge-hydrogen eluhlaza kuyunithi yegesi ecindezelwe, iyunithi yokwenziwa kwe-ethylene glycol, ukubuyiswa kwesibabule, kanye nokwelashwa kwendle, futhi ihlinzeka nge-nitrogen enomfutho ophezulu nophansi kumayunithi ahlukahlukene ephrojekthi ye-ethylene glycol yokuhlanza nokuvala, futhi ihlinzeka ngomoya womoya kanye nemishini.

A. INQUBO YOBUCHWEPHESHE

Imishini yokuhlukanisa umoya ye-KDON32000/19000 yaklanywa futhi yakhiqizwa yi-Newdraft, futhi isebenzisa uhlelo lokugeleza kwenqubo lokuhlanzwa okugcwele kwe-molecule ye-adsorption ephansi, ukupholisa indlela yokukhulisa i-air booster turbine, ukucindezela kwangaphakathi kwe-oxygen yomkhiqizo, ukucindezela kwangaphandle kwe-nitrogen ephansi, kanye nokujikeleza kwe-air booster. Umbhoshongo ongezansi usebenzisa umbhoshongo wepuleti lesivingo osebenza kahle kakhulu, kanti umbhoshongo ongaphezulu usebenzisa inqubo yokupakisha ehlelekile kanye nenqubo yokukhiqiza i-argon engena-hydrogen.

Umoya ongahluziwe udonswa ungene usuka endaweni yokungena, bese uthuli kanye nokunye ukungcola kwemishini kususwa yisihlungi somoya esizihlanzayo. Umoya ngemva kwesihlungi ungena kwi-compressor ye-centrifugal, futhi ngemva kokucindezelwa yi-compressor, ungena embhoshongweni wokupholisa umoya. Ngesikhathi uphola, ungahlanza nokungcola okuncibilika kalula emanzini. Umoya ngemva kokuphuma embhoshongweni wokupholisa ungena kwi-molecule sieve purifier yokushintsha. I-Carbon dioxide, i-acetylene kanye nomswakama emoyeni kuyamuncwa. I-molecular sieve purifier isetshenziswa ngezindlela ezimbili zokushintsha, enye yazo isebenza ngenkathi enye ivuselela. Umjikelezo wokusebenza we-purifier cishe amahora angu-8, futhi i-purifier eyodwa ishintshwa kanye njalo emahoreni angu-4, futhi ukushintsha okuzenzakalelayo kulawulwa uhlelo oluhlelekile.

Umoya ngemva kwe-molecular sieve adsorber uhlukaniswe ngemifudlana emithathu: umfudlana owodwa ukhishwa ngqo ku-molecule sieve adsorber njengomoya wethuluzi wemishini yokuhlukanisa umoya, umfudlana owodwa ungena ku-low-pressure plate-fin heat exchanger, upholiswa yi-reflux i-ammonia ne-ammonia engcolile, bese ungena embhoshongweni ongezansi, umfudlana owodwa uya ku-air booster, bese uhlukaniswa ngemifudlana emibili ngemva kokucindezelwa kwesigaba sokuqala se-booster. Umfudlana owodwa ukhishwa ngqo futhi usetshenziswe njengomoya wesistimu kanye nomoya wedivayisi ngemva kokunciphisa ingcindezi, kanti omunye umfudlana uyaqhubeka nokucindezela ku-booster futhi uhlukaniswe ngemifudlana emibili ngemva kokucindezela esigabeni sesibili. Umfudlana owodwa ukhishwa futhi upholiswe ekamelweni lokushisa bese uya ekugcineni kokukhulisa kwe-turbine expander ukuze kucindezelwe okwengeziwe, bese ukhishwa nge-high-pressure heat exchanger bese ungena ku-expander ukuze kwandiswe futhi kusebenze. Umoya omanzi owandisiwe ungena ku-gas-liquid separator, kanti umoya ohlukanisiwe ungena embhoshongweni ongezansi. Umoya owuketshezi okhishwe ku-gas-liquid separator ungena embhoshongweni ongezansi njengoketshezi oluphuma emoyeni oluyi-liquid reflux, kanti omunye umfudlana uyaqhubeka nokucindezela ku-booster kuze kube yilapho kucindezelwa esigabeni sokugcina, bese upholiswa ekamelweni lokushisa yi-cooler bese ungena ku-high-pressure plate-fin heat exchanger ukuze kushintshwe ukushisa nge-liquid oxygen kanye ne-reflux polluted nitrogen. Le ngxenye yomoya ophuma emoyeni ocindezelekile incibilikiswa. Ngemva kokuba umoya owuketshezi ukhishwe phansi kwe-heat exchanger, ungena embhoshongweni ongezansi ngemva kokubhoboza. Ngemva kokuba umoya uncibilikisiwe ekuqaleni embhoshongweni ongezansi, kutholakala umoya owuketshezi oluyi-lean, umoya oketshezi olucebile nge-oxygen, i-liquid nitrogen emsulwa kanye ne-high-purity ammonia. Umoya oketshezi oluyi-lean, umoya oketshezi olucebile nge-oxygen kanye ne-liquid nitrogen emsulwa kupholiswa kakhulu e-cooler bese kugoqwa embhoshongweni ongaphezulu ukuze kuqhutshekwe kuqhutshwe. I-liquid oxygen etholakala phansi kombhoshongo ongaphezulu icindezelwa yi-liquid oxygen pump bese ingena ku-high-pressure plate-fin heat exchanger ukuze kufudunyezwe kabusha, bese ingena kunethiwekhi yepayipi le-oxygen. I-liquid nitrogen etholakala phezulu kombhoshongo ongezansi ikhishwa bese ingena ethangini lokugcina i-ammonia ewuketshezi. I-ammonia ehlanzekile kakhulu etholakala phezulu kombhoshongo ongezansi ishiswa kabusha yi-heat exchanger enengcindezi ephansi bese ingena kunethiwekhi yepayipi le-ammonia. I-nitrogen enengcindezi ephansi etholakala engxenyeni engenhla yombhoshongo ongaphezulu ishiswa kabusha yi-low-pressure plate-fin heat exchanger bese iphuma ebhokisini elibandayo, bese icindezelwa ibe yi-0.45MPa yi-nitrogen compressor bese ingena kunethiwekhi yepayipi le-ammonia. Inani elithile le-argon fraction likhishwa phakathi kombhoshongo ongaphezulu bese lithunyelwa kumbhoshongo we-xenon ongahluziwe. Ingxenye ye-xenon ihluzwa embhoshongweni we-argon ongahluziwe ukuze kutholakale i-argon engahluziwe, bese ithunyelwa phakathi kombhoshongo we-argon ohluziwe. Ngemva kokuhluzwa embhoshongweni we-argon ohluziwe, i-xenon engahluziwe itholakala phansi kombhoshongo. Igesi ye-ammonia engcolile ikhishwa engxenyeni engenhla yombhoshongo ongaphezulu, futhi ngemva kokufudunyezwa kabusha yi-cooler, i-plate-fin heat exchanger enengcindezi ephansi kanye ne-plate-fin heat exchanger enengcindezi ephezulu bese iphuma ebhokisini elibandayo, ihlukaniswe izingxenye ezimbili: ingxenye eyodwa ingena ku-steam heater yesistimu yokuhlanza isihlungo sama-molecule njengegesi yokuvuselela isihlungo sama-molecule, kanti igesi ye-nitrogen engcolile esele iya embhoshongweni wokupholisa amanzi. Lapho uhlelo lokusekela umoya-mpilo oluwuketshezi ludinga ukuqaliswa, umoya-mpilo oluwuketshezi ethangini lokugcina umoya-mpilo oluwuketshezi lushintshwa lube yi-liquid oxygen vaporizer nge-valve elawulayo, bese lungena kunethiwekhi yepayipi lomoya-mpilo ngemva kokuthola umoya-mpilo ophansi; lapho uhlelo lokusekela umoya-mpilo oluwuketshezi ludinga ukuqaliswa, i-ammonia ewuketshezi ethangini lokugcina i-nitrogen oluwuketshezi ishintshwa ibe yi-liquid oxygen vaporizer nge-valve elawulayo, bese icindezelwa yi-ammonia compressor ukuze kutholakale i-nitrogen enengcindezi ephezulu kanye ne-ammonia enengcindezi ephansi, bese ingena kunethiwekhi yepayipi le-nitrogen.

B. UHLELO LOKULAWULA

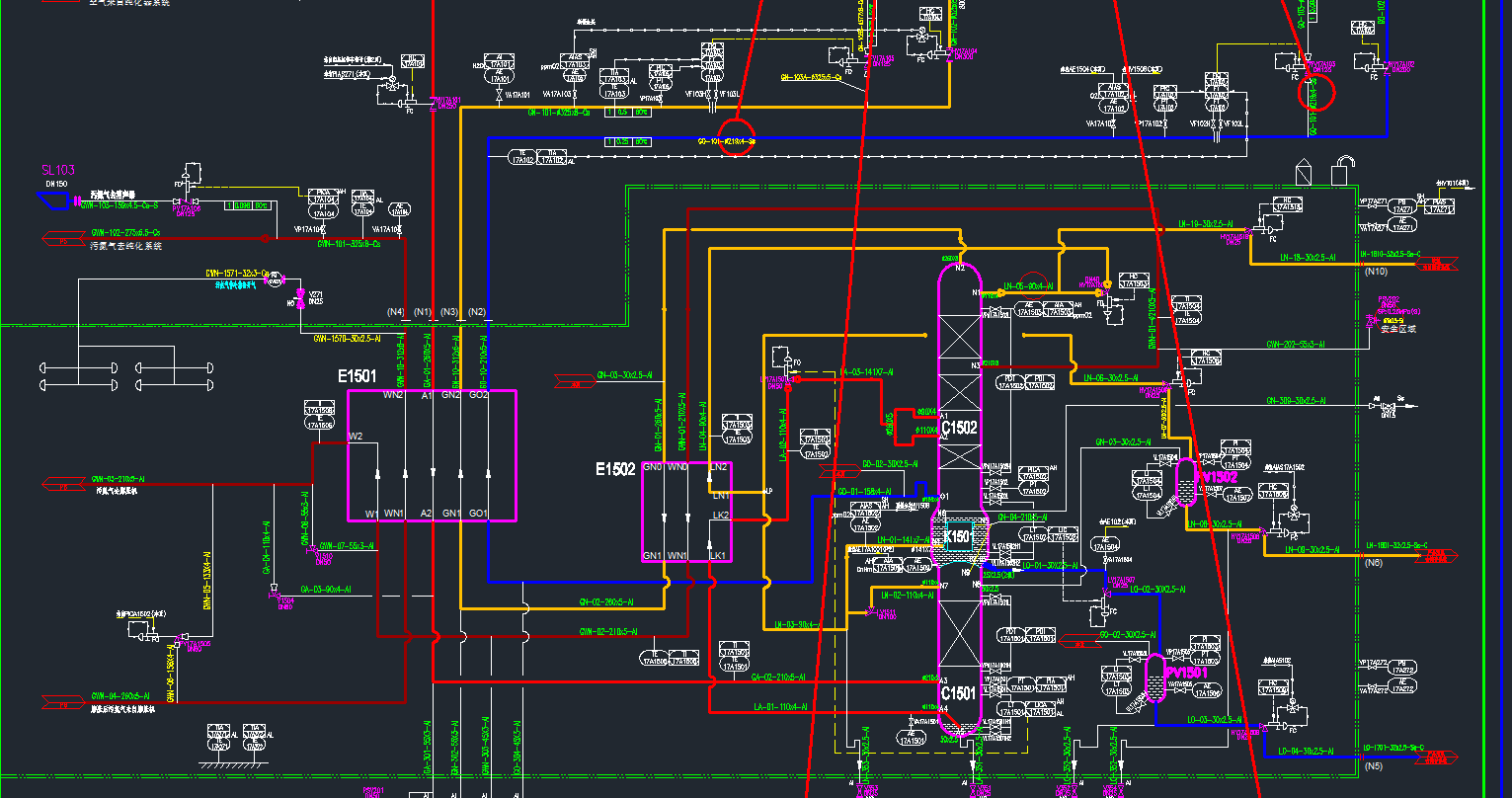

Ngokwesilinganiso kanye nezici zenqubo yemishini yokuhlukanisa umoya, uhlelo lokulawula olusatshalaliswa yi-DCS luyasetshenziswa, luhlanganiswe nokukhethwa kwezinhlelo ze-DCS ezithuthukisiwe emhlabeni wonke, abahlaziyi be-valve yokulawula online kanye nezinye izingxenye zokulinganisa nokulawula. Ngaphezu kokukwazi ukuqedela ukulawula inqubo yeyunithi yokuhlukanisa umoya, lungabeka futhi wonke ama-valve okulawula endaweni ephephile lapho iyunithi ivaliwe engozini, futhi amaphampu ahambisanayo angena esimweni sokuphepha sokuxhuma ukuqinisekisa ukuphepha kweyunithi yokuhlukanisa umoya. Amayunithi amakhulu e-turbine compressor asebenzisa izinhlelo zokulawula ze-ITCC (izinhlelo zokulawula ezihlanganisiwe ze-turbine compressor unit) ukuqedela ukulawula okuhamba ngesivinini esikhulu kweyunithi, ukulawula okuphuthumayo kanye nemisebenzi yokulawula yokulwa nokuqhuma, futhi angathumela izimpawu ohlelweni lokulawula lwe-DCS ngesimo sezintambo eziqinile kanye nokuxhumana.

C. Amaphuzu amakhulu okuqapha iyunithi yokuhlukanisa umoya

Ukuhlaziywa kobumsulwa kwe-oxygen yomkhiqizo kanye negesi ye-nitrogen eshiya i-heat exchanger ephansi, ukuhlaziywa kobumsulwa komoya oketshezi we-tower ephansi, ukuhlaziywa kwe-nitrogen ehlanzekile ye-tower ephansi, ukuhlaziywa kobumsulwa kwegesi eshiya i-tower engenhla, ukuhlaziywa kobumsulwa kwegesi efaka i-subcooler, ukuhlaziywa kobumsulwa kwe-oxygen ewuketshezi embhoshongweni ongaphezulu, izinga lokushisa ngemva kwe-condenser engcolile i-reflux liquid air constant flow valve, ingcindezi kanye ne-liquid level inkomba ye-distillation tower gas-liquid separator, inkomba yokushisa yegesi ye-nitrogen engcolile eshiya i-heat exchanger ephansi, ukuhlaziywa kobumsulwa komoya efaka i-heat exchanger ephansi, izinga lokushisa lomoya eshiya i-heat exchanger ephansi, umehluko wokushisa kanye nokushisa kwe-ammonia gas engcolile eshiya i-heat exchanger, ukuhlaziywa kwegesi e-upper tower xenon fraction extraction port: konke lokhu kusetshenziselwa ukuqoqa idatha ngesikhathi sokuqala nokusebenza okuvamile, okuzuzisa ukulungisa izimo zokusebenza zeyunithi yokuhlukanisa umoya nokuqinisekisa ukusebenza okuvamile kwemishini yokuhlukanisa umoya. Ukuhlaziywa kokuqukethwe kwe-nitrous oxide kanye ne-acetylene ekupholiseni okuyinhloko, kanye nokuhlaziywa kokuqukethwe komswakama emoyeni okhuphulayo: ukuze kuvinjelwe umoya onomswakama ukuthi ungangeni ohlelweni lokucwilisa, okubangela ukuqina nokuvimba isiteshi sokushintshanisa ukushisa, okuthinta indawo kanye nokusebenza kahle kokushintshanisa ukushisa, i-acetylene izoqhuma ngemva kokuba ukuqongelela ekupholiseni okuyinhloko kudlule inani elithile. Ukugeleza kwegesi yesivalo se-oxygen pump shaft, ukuhlaziywa kwengcindezi, izinga lokushisa lesifudumezi se-oxygen pump bearing, izinga lokushisa legesi yesivalo se-labyrinth, izinga lokushisa lomoya ngemva kokunwetshwa, ingcindezi yegesi yesivalo se-expander, ukugeleza, inkomba yokucindezela okuhlukile, ingcindezi kawoyela wokugcoba, izinga lethangi likawoyela kanye nokushisa kwangemuva kwesivalo se-oyela, ukuphela kokwandiswa kwe-turbine expander, ukugeleza kokungena kwe-booster end oil, izinga lokushisa lokuthwala, inkomba yokudlidliza: konke ukuqinisekisa ukusebenza okuphephile nokujwayelekile kwe-turbine expander kanye ne-liquid oxygen pump, futhi ekugcineni ukuqinisekisa ukusebenza okujwayelekile kokuhlukaniswa komoya.

Ukushisa kwe-molecular sieve ingcindezi eyinhloko, ukuhlaziywa kokugeleza, amazinga okushisa okungena kanye nokuphuma kwe-molecule sieve (i-nitrogen engcolile), inkomba yokucindezela, izinga lokushisa kanye nokugeleza kwe-molecule sieve, inkomba yokumelana nesistimu yokuhlanza, inkomba yomehluko we-molecule sieve outlet pressure, izinga lokushisa lokungena kwe-steam, i-alamu yenkomba yokucindezela, i-H20 analysis heater H20, i-alamu ye-condensate outlet temperature, i-CO2 air outlet sieve, inkomba ye-CO2 air inlet ephansi kanye nokugeleza kwe-booster: ukuqinisekisa ukusebenza okuvamile kokushintsha kwesistimu ye-adsorption ye-molecule sieve nokuqinisekisa ukuthi okuqukethwe kwe-CO2 kanye ne-H20 komoya okungena ebhokisini elibandayo kusezingeni eliphansi. Inkomba yokucindezela komoya wensimbi: ukuqinisekisa ukuthi umoya wensimbi wokuhlukanisa umoya kanye nomoya wensimbi ohlinzekwa kunethiwekhi yamapayipi kufinyelela ku-0.6MPa (G) ukuqinisekisa ukusebenza okuvamile kokukhiqiza.

D. Izici zeyunithi yokuhlukanisa umoya

1. Izici zenqubo

Ngenxa yokucindezela okuphezulu kwe-oxygen kwephrojekthi ye-ethylene glycol, imishini yokuhlukanisa umoya ye-KDON32000/19000 isebenzisa umjikelezo wokukhulisa umoya, ukucindezela kwangaphakathi kwe-oxygen kanye nenqubo yokucindezela kwangaphandle kwe-ammonia, okungukuthi, i-air booster + i-liquid oxygen pump + i-booster turbine expander ihlanganiswa nokuhleleka okufanelekile kohlelo lokushintshanisa ukushisa ukuze kuthathelwe indawo i-oxygen compressor yenqubo yokucindezela kwangaphandle. Izingozi zokuphepha ezibangelwa ukusetshenziswa kwama-oxygen compressors enqubweni yokucindezela kwangaphandle ziyancishiswa. Ngesikhathi esifanayo, inani elikhulu le-oxygen ewuketshezi ekhishwe ukupholisa okuyinhloko lingaqinisekisa ukuthi amathuba okuqongelela kwe-hydrocarbon ku-oxygen ewuketshezi epholile ancishisiwe ukuqinisekisa ukusebenza okuphephile kwemishini yokuhlukanisa umoya. Inqubo yokucindezela kwangaphakathi inezindleko zokutshalwa kwezimali eziphansi kanye nokulungiswa okunengqondo kakhudlwana.

2. Izici zemishini yokuhlukanisa umoya

Isihlungi somoya esizihlanzayo sifakwe uhlelo lokulawula oluzenzakalelayo, olungabuyisela emuva ngokuzenzakalelayo futhi lulungise uhlelo ngokuya ngosayizi wokumelana. Uhlelo lokupholisa ngaphambi kokupholisa lusebenzisa umbhoshongo wokupakisha ongahleliwe osebenza kahle kakhulu futhi ongamelani kakhulu, kanti umsabalalisi woketshezi usebenzisa umsabalalisi omusha, osebenzayo futhi othuthukile, ongagcini nje ngokuqinisekisa ukuxhumana okugcwele phakathi kwamanzi nomoya, kodwa futhi oqinisekisa ukusebenza kokushintshana kokushisa. I-wire mesh demister isethwe phezulu ukuqinisekisa ukuthi umoya ophuma embhoshongweni wokupholisa umoya awuthwali amanzi. Uhlelo lokumuncwa kwesihlungo sama-molecule lusebenzisa umjikelezo omude kanye nokuhlanzwa kombhede okunezingqimba ezimbili. Uhlelo lokushintsha lusebenzisa ubuchwepheshe bokulawula ukushintshana okungenamthelela, futhi kusetshenziswa i-heater ekhethekile yomusi ukuvimbela umusi wokushisa ukuthi ungaphumi uye ohlangothini lwe-nitrogen olungcolile ngesikhathi sesigaba sokuvuselela.

Yonke inqubo yesistimu yombhoshongo wokuhluza isebenzisa ukubalwa kokulingisa kwesofthiwe ye-ASPEN ne-HYSYS okuthuthukisiwe emhlabeni wonke. Umbhoshongo ongezansi usebenzisa umbhoshongo wepuleti lesivingo osebenza kahle kakhulu kanti umbhoshongo ongaphezulu usebenzisa umbhoshongo wokupakisha ojwayelekile ukuqinisekisa izinga lokukhipha idivayisi nokunciphisa ukusetshenziswa kwamandla.

E. Ingxoxo ngenqubo yokwehlisa nokulayisha izimoto ezine-air conditioner

1. Imibandela okufanele ihlangatshezwane nayo ngaphambi kokuqala ukuhlukaniswa komoya:

Ngaphambi kokuqala, hlela futhi ubhale uhlelo lokuqala, okuhlanganisa inqubo yokuqala kanye nokuphathwa kwezingozi eziphuthumayo, njll. Yonke imisebenzi ngesikhathi senqubo yokuqala kumele yenziwe endaweni.

Ukuhlanza, ukuhlanza kanye nokusebenza kokuhlola uhlelo lwamafutha okugcoba kuqediwe. Ngaphambi kokuqala ipompo yamafutha okugcoba, igesi yokuvala kumele ifakwe ukuze kuvinjelwe ukuvuza kwamafutha. Okokuqala, ukuhlunga okuzijikeleza kwethangi lamafutha okugcoba kumele kwenziwe. Lapho kufinyelelwa izinga elithile lokuhlanzeka, ipayipi lamafutha lixhunywe ukuze kuhlanzwe futhi kuhlungwe, kodwa iphepha lokuhlunga liyangezwa ngaphambi kokungena kwi-compressor kanye ne-turbine futhi lihlala lishintshwa ukuqinisekisa ukuhlanzeka kwamafutha angena emishinini. Ukuhlanza kanye nokusebenza kohlelo lwamanzi olujikelezayo, uhlelo lokuhlanza amanzi, kanye nohlelo lokukhipha amanzi lokuhlukaniswa komoya kuyaqedwa. Ngaphambi kokufakwa, ipayipi elicebile nge-oxygen lokuhlukaniswa komoya kudingeka lisuswe amafutha, lifakwe usawoti, futhi lingasebenzi, bese ligcwaliswa ngegesi yokuvala. Amapayipi, imishini, kagesi, kanye nezinsimbi (ngaphandle kwezinsimbi zokuhlaziya kanye nezinsimbi zokulinganisa) zemishini yokuhlukanisa umoya zifakiwe futhi zalinganiswa ukuze zifaneleke.

Zonke izimpompi zamanzi ezisebenzayo, amaphampu e-oxygen ewuketshezi, ama-air compressor, ama-booster, ama-turbine expanders, njll. zinemibandela yokuqala, futhi ezinye kufanele zihlolwe emshinini owodwa kuqala.

Uhlelo lokushintsha isihlungi sama-molecule lunemibandela yokuqala, futhi uhlelo lokushintsha ama-molecule luqinisekisiwe ukuthi luyakwazi ukusebenza ngokujwayelekile. Ukushisa nokuhlanza ipayipi lomusi elinomfutho ophezulu sekuqediwe. Uhlelo lomoya wezinsimbi olulindile selusetshenzisiwe, lugcina umfutho womoya wezinsimbi ungaphezu kuka-0.6MPa(G).

2. Ukususa amapayipi okuhlukanisa umoya

Qala uhlelo lwamafutha okugcoba kanye nohlelo lwegesi lokuvala lwe-turbine yomusi, i-air compressor kanye nephampu yamanzi okupholisa. Ngaphambi kokuqala i-air compressor, vula i-vent valve ye-air compressor bese uvala indawo yokungena komoya yombhoshongo wokupholisa umoya ngepuleti eliyimpumputhe. Ngemva kokuba ipayipi lokukhipha i-air compressor selihlanziwe, ingcindezi yokukhipha ifinyelela ingcindezi yokukhipha elinganiselwe futhi ithagethi yokuhlanza ipayipi isifanelekile, xhuma ipayipi lokungenisa umoya elipholile, qala uhlelo lokupholisa umoya ngaphambi kokuhlanza (ngaphambi kokuhlanza, ukupakisha umbhoshongo wokupholisa umoya akumelwe kugcwaliswe; i-flange yokungenisa umoya ye-molecule sieve adsorber isivimbo sokungenisa umoya inqanyuliwe), linda kuze kube yilapho ithagethi isifanelekile, qala uhlelo lokuhlanza i-molecular sieve (ngaphambi kokuhlanza, i-molecule sieve adsorber adsorbent akumelwe igcwaliswe; i-flange yokungenisa umoya ebandayo ebhokisini lokungenisa umoya kumele inqanyulwe), misa i-air compressor kuze kube yilapho ithagethi isifanelekile, gcwalisa ukupakisha kombhoshongo wokupholisa umoya kanye ne-molecule sieve adsorber adsorbent, bese uqala kabusha isihlungi, i-steam turbine, i-air compressor, uhlelo lokupholisa umoya ngaphambi kokupholisa, uhlelo lokungenisa i-molecular sieve ngemva kokugcwalisa, okungenani amasonto amabili okusebenza okuvamile ngemva kokuvuselelwa, ukupholisa, ukwanda kwengcindezi, ukumuncwa, kanye nokunciphisa ingcindezi. Ngemva kwesikhathi sokushisa, amapayipi omoya wesistimu ngemva kwe-molecule sieve adsorber kanye namapayipi angaphakathi ombhoshongo wokuhlukaniswa angavuthelwa. Lokhu kufaka phakathi ama-heat exchanger anomfutho ophezulu, ama-heat exchanger anomfutho ophansi, ama-air booster, ama-turbine expander, kanye nemishini yombhoshongo ephathelene nokuhlukaniswa komoya. Naka ukulawula ukugeleza komoya okungena ohlelweni lokuhlanzwa kwesihlungo sama-molecule ukuze ugweme ukumelana okukhulu kwesihlungo sama-molecule okulimaza ungqimba lombhede. Ngaphambi kokushaya umbhoshongo wokuhlukaniswa, wonke amapayipi omoya angena ebhokisini elibandayo lombhoshongo wokuhlukaniswa kumele afakwe izihlungi zesikhashana ukuvimbela uthuli, i-welding slag kanye nokunye ukungcola ukuthi kungangeni ku-heat exchanger futhi kuthinte umphumela wokushintshana kokushisa. Qala uhlelo lwegesi lokuthambisa uwoyela kanye nokuvala ngaphambi kokushaya i-turbine expander kanye nephampu ye-oxygen ewuketshezi. Wonke amaphuzu okuvala igesi emishini yokuhlukanisa umoya, kufaka phakathi i-nozzle ye-turbine expander, kumele avalwe.

3. Ukupholisa okungenalutho kanye nokuqaliswa kokugcina kweyunithi yokuhlukanisa umoya

Wonke amapayipi angaphandle kwebhokisi elibandayo ayapheshulwa, futhi wonke amapayipi nemishini ebhokisini elibandayo ayafudunyezwa futhi apheshulwe ukuze kuhlangatshezwane nezimo zokupholisa futhi kulungiselelwe ukuhlolwa kokupholisa okungenalutho.

Lapho kuqala ukupholisa kombhoshongo wokuhluza, umoya okhishwa yi-air compressor awukwazi ukungena ngokuphelele embhoshongweni wokuhluza. Umoya ocindezelwe ngokweqile ukhishwa emoyeni nge-vent valve, ngaleyo ndlela ugcine ingcindezi yokukhipha i-air compressor ingashintshi. Njengoba izinga lokushisa lengxenye ngayinye yombhoshongo wokuhluza lincipha kancane kancane, inani lomoya ophefumulwayo lizokhula kancane kancane. Ngalesi sikhathi, ingxenye yegesi ye-reflux embhoshongweni wokuhluza ithunyelwa embhoshongweni wokupholisa amanzi. Inqubo yokupholisa kufanele yenziwe kancane futhi ngokulinganayo, ngesilinganiso sokupholisa esimaphakathi esingu-1 ~ 2℃/h ukuqinisekisa izinga lokushisa elifanayo lengxenye ngayinye. Ngesikhathi senqubo yokupholisa, amandla okupholisa esandisi segesi kufanele agcinwe ephezulu kakhulu. Lapho umoya ekugcineni okubandayo kwe-heat exchanger eyinhloko useduze nokushisa kokuhluza, isigaba sokupholisa siyaphela.

Isigaba sokupholisa sebhokisi elibandayo sigcinwa isikhathi esithile, futhi ukuvuza okuhlukahlukene nezinye izingxenye ezingakaqedwa kuyahlolwa futhi kulungiswe. Bese umisa umshini isinyathelo ngesinyathelo, qala ukulayisha isihlabathi samaparele ebhokisini elibandayo, qala imishini yokuhlukanisa umoya isinyathelo ngesinyathelo ngemva kokulayisha, bese uphinda ungene esigabeni sokupholisa. Qaphela ukuthi lapho imishini yokuhlukanisa umoya iqalwa, igesi yokuvuselela yesihlungo sama-molecule isebenzisa umoya ohlanziwe ngesihlungo sama-molecule. Lapho imishini yokuhlukanisa umoya iqalwa futhi kunegesi yokuvuselela eyanele, kusetshenziswa indlela yokugeleza kwe-ammonia engcolile. Ngesikhathi senqubo yokupholisa, izinga lokushisa ebhokisini elibandayo liyancipha kancane kancane. Uhlelo lokugcwalisa i-ammonia yebhokisi elibandayo kufanele luvulwe ngesikhathi ukuvimbela ingcindezi engemihle ebhokisini elibandayo. Ngemuva kwalokho imishini esebhokisini elibandayo ipholiswa kakhulu, umoya uqala ukuncibilika, uketshezi luqala ukuvela embhoshongweni ongezansi, futhi inqubo yokuhlanza imibhoshongo ephezulu nengezansi iqala ukusungulwa. Bese ulungisa kancane kancane ama-valve ngamunye ngamunye ukuze wenze ukuhlukaniswa komoya kusebenze ngokujwayelekile.

Uma ufuna ukwazi ulwazi olwengeziwe, sicela uxhumane nathi ngokukhululekile:

Xhumana: Lyan.Ji

Ucingo: 008618069835230

Mail: Lyan.ji@hznuzhuo.com

I-Whatsapp: 008618069835230

I-WeChat: 008618069835230

Isikhathi sokuthunyelwe: Ephreli-24-2025

Ucingo: 0086-15531448603

Ucingo: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com