Ukuhlukaniswa komoya ocryogenic okujulile kuyinqubo ehlukanisa umoya-mpilo, i-nitrogen kanye namanye amagesi emoyeni kusetshenziswa ubuchwepheshe obuphansi. Njengendlela ethuthukisiwe yokukhiqiza igesi yezimboni, ukuhlukaniswa komoya ocryogenic okujulile kusetshenziswa kabanzi ezimbonini ezifana ne-metallurgy, ubunjiniyela bamakhemikhali, kanye ne-elekthronikhi. Ukwakhiwa kwemishini ephelele yokuhlukanisa umoya ocryogenic okujulile akudingi nje ukunemba kobuchwepheshe kodwa futhi nokuhambisana nezindinganiso zezimboni kanye nezidingo zamakhasimende ukuqinisekisa ukusebenza okuzinzile kanye nezinzuzo zezomnotho. Lesi sihloko sizoxoxa ngezidingo zokuklama zemishini ephelele yokuhlukanisa umoya ocryogenic okujulile, sihlanganise izinto ezibalulekile zokuklama, amaphuzu obunjiniyela, kanye nezinyathelo zokuphepha ezisetshenziswayo.

1. Izidingo eziyisisekelo zokuklama

Uma uklama imishini yokuhlukanisa umoya ejulile e-cryogenic, izidingo zokuqala eziyisisekelo okufanele zinqunywe zifaka phakathi umthamo wokukhiqiza, izimo zomoya ezingavuthiwe, ubumsulwa bomkhiqizo kanye nobuningi, njll. Kuye ngezinkambu ezahlukene zokusetshenziswa, umthamo wokukhiqiza wemishini yokuhlukanisa umoya ejulile e-cryogenic uyahlukahluka kakhulu, ngokuvamile kusukela kumakhulu kuya ezinkulungwaneni zama-cubic metres ngehora. Ngaphezu kwalokho, ukungcola emoyeni ongavuthiwe, njengomswakama kanye ne-carbon dioxide, kudinga ukususwa ngesigaba sangaphambi kokwelashwa ukuqinisekisa ukuthi imishini ingenza imisebenzi ejulile e-cryogenic ngaphansi kwezimo ezizinzile nezingenakuphazamiseka. Ngakho-ke, ukwakheka kohlelo lwangaphambi kokwelashwa kudinga ukucabangela ngokugcwele amazinga okungcola komoya wendawo kanye nendawo yokusebenza yemishini.

2. Izinto okufanele uzicabangele ngokuklama uhlelo

Inqubo yokuklama imishini yokuhlukanisa umoya ejulile e-cryogenic ihilela izinhlelo eziningi ezibalulekile, okuhlanganisa uhlelo lokucindezela, uhlelo lokushintshanisa ukushisa, uhlelo lokuhlukanisa umbhoshongo kanye nohlelo lokuhlanza. Ukwakheka kohlelo lokucindezela kudinga ukuqinisekisa ukuhlinzekwa komoya ocindezelekile okusebenza kahle futhi okuthembekile okufanelekela ukuhlukaniswa okujulile kwe-cryogenic. Ama-heat exchanger yizingxenye eziyinhloko eziqinisekisa ukufezwa kwenqubo ye-cryogenic ejulile, edinga ukusebenza kahle kokushisa okuphezulu. Ngokuvamile, ama-plate-fin heat exchanger asetshenziselwa ukuqinisekisa ukudluliselwa kokushisa okusebenzayo kanye nokugeleza kwegesi okufanayo. Ngesikhathi esifanayo, ukwakheka kombhoshongo wokuhlukanisa kanye nohlelo lokuhlanza kudinga ukuhlangabezana nezidingo zobumsulwa begesi yomkhiqizo, ngakho-ke ukukhethwa kokupakisha, amathreyi kanye nokwenza ngcono izimo zenqubo yokuhlanza nakho kubaluleke kakhulu. Embhoshongweni wokuhlanza, izingxenye ezahlukene zegesi zihlukaniswa ngempumelelo ngezinqubo zokushintshanisa ukushisa eziphindaphindwayo kanye nokuhwamuka kwe-condensation, kwakha amagesi e-oxygen, i-nitrogen noma i-argon ahlanzekile kakhulu.

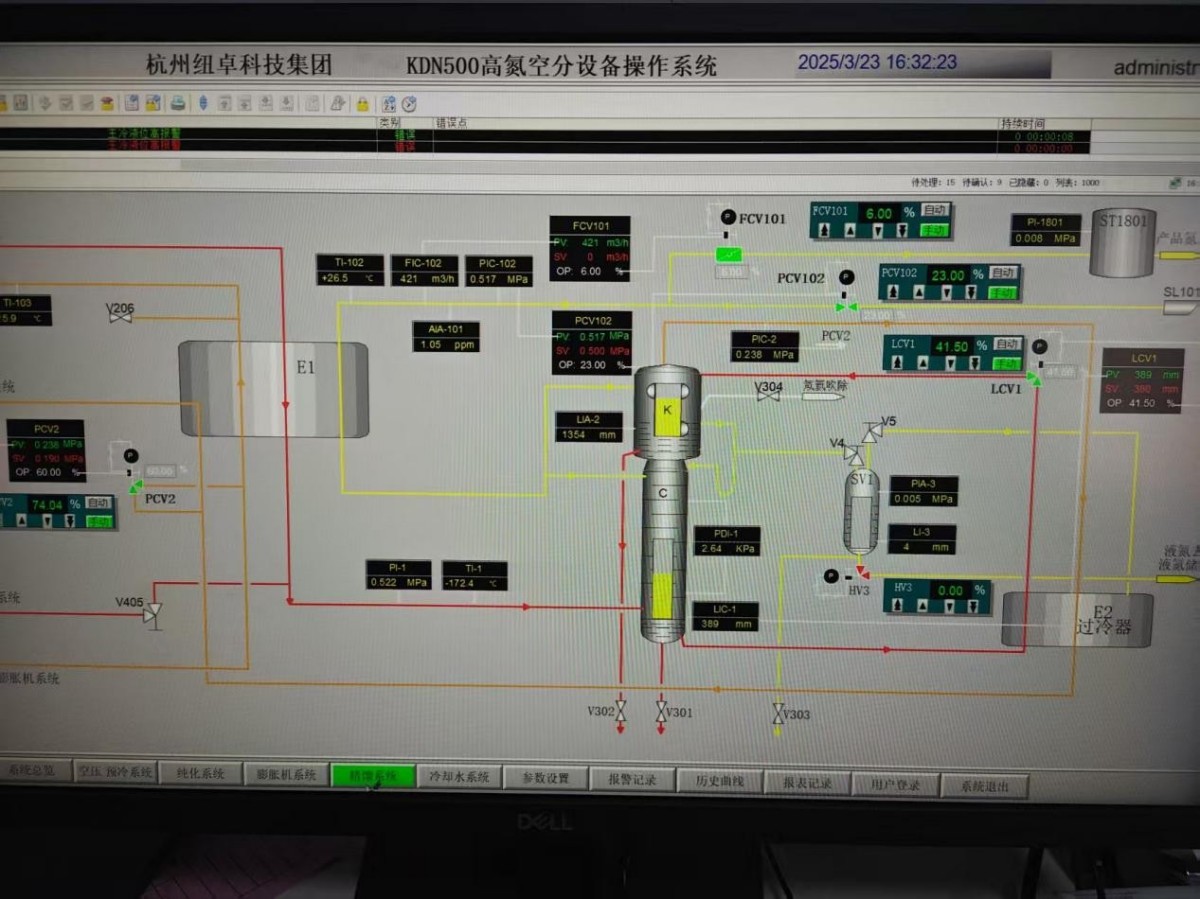

3. Izinhlelo zokwenza izinto ngokuzenzakalelayo kanye nokulawula

Ukulawula okuzenzakalelayo kuyingxenye ebalulekile yokwakhiwa kwezinhlelo zokuhlukanisa umoya ezijulile ezi-cryogenic. Imishini yokuhlukanisa umoya ejulile ejulile yesimanje ivame ukuhlanganisa uhlelo lokulawula oluzenzakalelayo ngokuphelele ukuze kufezwe ukulawula okunembile kwamapharamitha afana nokushisa, ingcindezi kanye nokugeleza. Lokhu akugcini nje ngokunciphisa ubunzima bokusebenza kodwa futhi kuthuthukisa ukuphepha nokuzinza kohlelo. Uhlelo lokulawula inqubo luvame ukuba ne-PLC (Programmable Logic Controller) kanye ne-DCS (Distributed Control System), eziqoqa amapharamitha ayisihluthulelo ngesikhathi sangempela sokulawula nokwenza ngcono, ukuqinisekisa ukusebenza okuzinzile kwemishini ngaphansi kwezimo ezahlukahlukene zomthwalo. Ukuze ibhekane nezimo eziphuthumayo, uhlelo lokulawula ludinga futhi ukuba namakhono okuxilonga amaphutha, olukwazi ukubona izinkinga ezingaba khona ngokushesha futhi luthathe izinyathelo ezifanele.

4. Izinto ezicatshangelwa ukonga amandla kanye nokuvikelwa kwemvelo

Ukonga amandla kuyinto ebalulekile ekwakhiweni kwemishini yokuhlukanisa umoya ejulile e-cryogenic. Ukwakheka kahle kwama-compressor kanye nama-heat exchanger kudlala indima ebalulekile ekunciphiseni ukusetshenziswa kwamandla. Ngaphezu kwalokho, ukubuyisa ukushisa okulahliwe kuyindlela evamile yokonga amandla, engasebenzisa ukushisa okulahliwe okuvela enkambisweni yokuqandisa ukuze inikeze ukwesekwa kwamandla kwezinye izinqubo, ngaleyo ndlela ithuthukise ukusebenza kahle kokusetshenziswa kwamandla. Ngokuphathelene nokuvikelwa kwemvelo, ukwakheka kokuhlukanisa umoya ejulile e-cryogenic kudinga ukucabangela ngokugcwele izinkinga ezingaba khona zokungcoliswa kwemvelo enkambisweni yokukhiqiza, njengokungcola komsindo kanye nokukhishwa kwegesi ephumayo. Ngesikhathi sesigaba sokuklama, ukwelashwa kokufakwa komsindo kanye nezinhlelo ezifanele zokwelashwa kwegesi ephumayo kudingeka kwengezwe ukuze kuhlangatshezwane nemithethonqubo efanele yokuvikelwa kwemvelo kanye nezidingo zezindinganiso.

5. Ukusebenza kahle kwezindleko kanye nokukhethwa kwemishini

Ukuhlolwa kokusebenza kahle kwezindleko kwemishini ephelele yokuhlukanisa umoya ejulile e-cryogenic kuthinta ngqo ukwakheka kwayo kanye nokukhetha kwayo. Ngaphansi kwesisekelo sokuhlangabezana nezidingo zokukhiqiza, ukukhethwa kanye nobukhulu bemishini kudingeka kube phansi ngangokunokwenzeka ngokwezindleko zokutshalwa kwezimali kokuqala kanye nezindleko zokusebenza. Ukukhethwa kwezinto zokukhiqiza, ukusebenza kahle kokushintshana kokushisa, izinhlobo zama-compressor kanye nokukhetha kokugeleza kwenqubo konke kuyizinto ezibalulekile ezithinta ukusebenza kahle kwezindleko. Ukukhethwa kwemishini efanele akugcini nje ngokunciphisa ukutshalwa kwezimali kokuqala kodwa futhi kunciphisa ngempumelelo izindleko zokugcinwa kanye nokusebenza ngokuhamba kwesikhathi, ngaleyo ndlela kutholakale imbuyiselo ephezulu yezomnotho ngesikhathi senqubo yokukhiqiza.

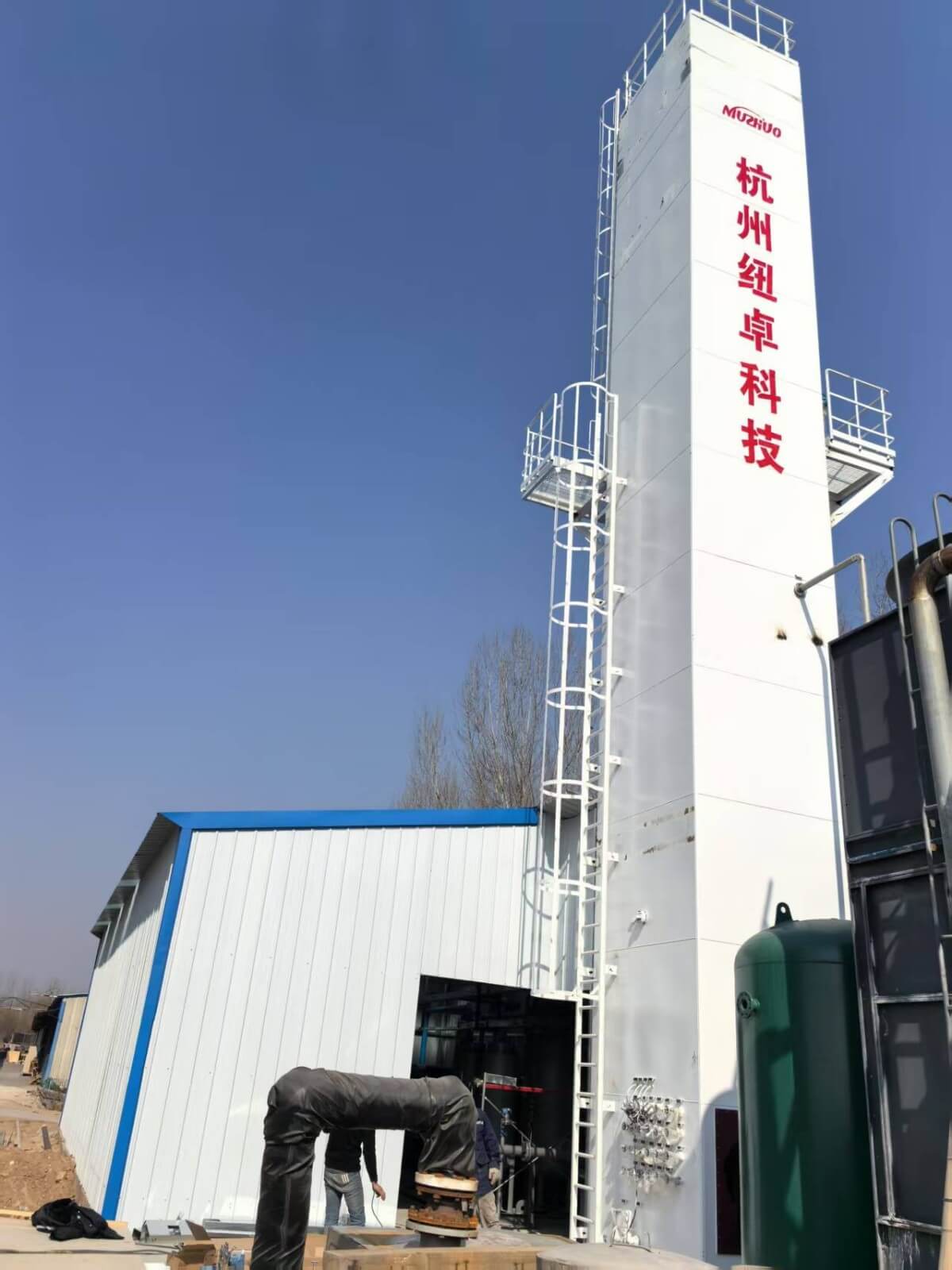

6. Ukufakwa Nokuqaliswa Kwemisebenzi Esizeni

Ukwakhiwa kwemishini yokuhlukanisa umoya ejulile e-cryogenic akugcini nje esigabeni sokudweba; kudinga futhi ukucabangela izidingo zokufakwa kanye nokuqaliswa endaweni. Ngesikhathi sesigaba sokufaka, ukuhlelwa okunembile kwengxenye ngayinye kumele kuqinisekiswe ukugwema ukuvuza ekuxhumeni kwamapayipi. Ngesikhathi senqubo yokuqaliswa, ukuhlolwa okuphelele kwesimo sokusebenza kwesistimu ngayinye kuyadingeka ukuqinisekisa ukuthi imishini isebenza esimweni sayo esifanele. Ngenxa yobunzima bemishini yokuhlukanisa umoya ejulile e-cryogenic, ukuqaliswa kuvame ukwenziwa yithimba lobunjiniyela abangochwepheshe, okuhlanganisa ukuhlolwa okuningi kanye nokulungiswa kwamapharamitha afana nokuhlanzeka kwegesi, ingcindezi, kanye nesivinini sokugeleza, ekugcineni kuhlangabezana nezidingo zomklamo kanye namazinga amakhasimende.

Ngezinguquko eziqhubekayo ezidingweni zezimboni kanye nentuthuko yezobuchwepheshe, ukwakheka kwemishini yokuhlukanisa umoya we-cryogenic ejulile nakho kuthuthukiswa njalo. Imishini yokuhlukanisa umoya we-cryogenic ejulile yesikhathi esizayo izogcizelela kakhulu ubuhlakani kanye nohlaza. Ngokwethula ubuchwepheshe bokuzwa obuthuthukisiwe kanye nobuchwepheshe be-Internet of Things (IoT), imishini ingafinyelela ukuqapha nokuphatha okukude, futhi ingenza ngcono ukusetshenziswa kwamandla ngempumelelo. Ngaphezu kwalokho, ukusetshenziswa kwezinto ezintsha, njengezinto zokushintshanisa ukushisa ezisebenza kahle kanye nezinto zokwakha ezingashisi kakhulu, kuzothuthukisa ukusebenza kanye nokuphila kwemishini. Esimweni sokuguqulwa okuqhubekayo kwesakhiwo samandla, imishini yokuhlukanisa umoya we-cryogenic ejulile nayo izosetshenziswa kabanzi ekukhiqizweni kwamandla ahlanzekile njenge-hydrogen, okufaka isandla ekufezweni komgomo wokungathathi hlangothi kwekhabhoni.

Uma unezidingo ze-oxygen/nitrogen, sicela uxhumane nathi:

Anna Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Isikhathi sokuthunyelwe: Juni-23-2025

Ucingo: 0086-15531448603

Ucingo: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com