I-HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

Inqubo Yokuhlukaniswa Komoya we-NUZHUO Ijeneretha Ye-Nitrogen Ene-Cryogenic I-Nitrogen Ehlanzekile Kakhulu Evela Emoyeni

| Igama Lomkhiqizo | Imishini yokuhlukanisa umoya we-Cryogenic |

| Inombolo Yemodeli | NZDON- 5/10/20/40/60/80/KWENZIWE NGOKUFANELEKILE |

| Umkhiqizo | NuZhuo |

| Izesekeli | I-Air compressor kanye nesistimu yokupholisa kabusha kanye ne-Expander |

| Ukusetshenziswa | Umshini wokukhiqiza i-Oxygen & Nitrogen & Argon ohlanzekile kakhulu |

| Imodeli | I-KDON-50/50 | I-KDON-80/160 | I-KDON-180/300 | I-KDON-260/500 | I-KDON-350/700 | I-KDON-550/1000 | I-KDON-750/1500 | I-KDON-1200/2000/0y |

| O2 0output (Nm3/h) | 50 | 80 | 180 | 260 | 350 | 550 | 750 | 1200 |

| O2 Ubumsulwa (%O2) | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 |

| Ukuphuma kwe-N2 0 (Nm3/h) | 50 | 160 | 300 | 500 | 700 | 1000 | 1500 | 2000 |

| Ubumsulwa be-N2 (PPm O2) | 9.5 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| I-Liquid Argon Ouput (Nm3/h) | —— | —— | —— | —— | —— | —— | —— | 30 |

| Ukuhlanzeka kwe-Argon Emanzi (Ppm O2 + PPm N2) | —— | —— | —— | —— | —— | —— | —— | ≤1.5ppmO2 + 4 pp mN2 |

| Ukuhlanzeka kwe-Argon Emanzi (Ppm O2 + PPm N2) | —— | —— | —— | —— | —— | —— | —— | 0.2 |

| Ukusetshenziswa (Kwh/Nm3 O2) | ≤1.3 | ≤0.85 | ≤0.68 | ≤0.68 | ≤0.65 | ≤0.65 | ≤0.63 | ≤0.55 |

| Indawo Ehlalwe Kuyo (m3) | 145 | 150 | 160 | 180 | 250 | 420 | 450 | 800 |

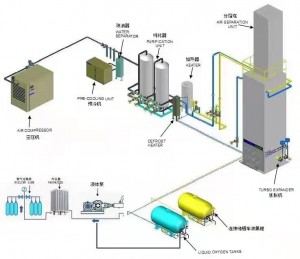

1. I-Air Compressor: Umoya ucindezelwa ngomfutho ophansi webha engu-5-7 (0.5-0.7mpa). Lokhu kwenziwa ngokusebenzisa ama-compressor akamuva (Uhlobo lwe-Screw/Centrifugal).

2. Uhlelo Lokupholisa Ngaphambi Kokubanda: Isigaba sesibili senqubo sihilela ukusetshenziswa kwesiqandisi ukuze kupholiswe umoya ocutshunguliwe kuze kufike ezingeni lokushisa elicishe libe ngu-12 deg C ngaphambi kokuba ungene ku-purifier.

3. Ukuhlanzwa Komoya Ngesihlanzi: Umoya ungena ku-purifier, eyakhiwe yi-two molecular Sieve dryer esebenza ngenye indlela. I-Molecular Sieve ihlukanisa i-carbon dioxide kanye nomswakama emoyeni wenqubo ngaphambi kokuba umoya ufike e-Unit yokuhlukanisa umoya.

4. Ukupholisa Umoya Okune-Cryogenic Nge-Expander: Umoya kumele upholiswe kuze kufike emazingeni okushisa angaphansi kwezinga ukuze kuncibilike. Ukuqandisa kanye nokupholisa okune-cryogenic kunikezwa yi-turbo expander esebenza kahle kakhulu, epholisa umoya kuze kufike emazingeni okushisa angaphansi kuka -165 kuya ku-170 degrees C.

5. Ukuhlukaniswa Komoya Owuketshezi Kube Umoya-mpilo Ne-Nitrogen Ngokuhlukaniswa Komoya

6. Ikholomu: Umoya ongena ku-heat exchanger yohlobo lwe-low pressure plate fin awunawo umswakama, awunawo uwoyela futhi awunayo i-carbon dioxide. Upholiswa ngaphakathi kwe-heat exchanger ngaphansi kwamazinga okushisa angaphansi kwezinga-zero ngenqubo yokukhulisa umoya ku-expander.

7. Kulindeleke ukuthi sifinyelele izinga lokushisa eliphansi njenge-2 degrees Celsius ekugcineni okufudumele kwama-exchanger. Umoya uyancibilika uma ufika kukholomu yokuhlukanisa umoya bese uhlukaniswa ube yi-oxygen ne-nitrogen ngenqubo yokulungisa.

I-oksijini Emanzi Igcinwa Ethangini Lokugcina Uketshezi: I-oksijini emanzi igcwaliswa ethangini lokugcina uketshezi elixhunywe kumshini wokwenza uketshezi okwakha uhlelo oluzenzakalelayo. Ipayipi lepayipi lisetshenziselwa ukukhipha i-oksijini emanzi ethangini.

UMA UNEZINTO EZIFUNWAYO ZOKWAZI ULWAZI OLUTHE NGEZIWE, THINTANA NATHI KU: 0086-18069835230

Iphrofayela Yenkampani

Isitifiketi kanye ne-NUZHUO

Q1: Ingabe uyinkampani yokuhweba noma umenzi?

Q3: Isikhathi sakho sokulethwa singakanani?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: Iyini inqubomgomo yakho yokuqinisekisa ikhwalithi yomkhiqizo?

Q5: Ingabe ninikeza isevisi ye-OEM/ODM?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comUmbuzo 6: Ingabe umkhiqizo wakho usetshenzisiwe noma musha? Umkhiqizo we-RTS noma umkhiqizo owenziwe ngokwezifiso?

Izigaba Zomkhiqizo

Gxila ekuhlinzekeni ngezixazululo ze-mong pu iminyaka emi-5.

Ucingo: 0086-15531448603

Ucingo: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com